Blood, sweat and tears.

The explosives specialist is making his way forward, sniffing parcels and crates to the left and right – routine work for the German shepherd at CargoCity Süd at Frankfurt Airport. Among the shipments that go through a final security check here at UPS Global Freight Forwarding before they are made ready for transport is a wooden box containing guitars that were made just a few miles from the airport: at the production facility of Nik Huber Guitars in Rodgau. Here an eight-member team builds around 240 instruments a year – putting a great many hours of manual labor into each of the guitars. It is an effort that is much appreciated by musicians from around the world – including rock stars in bands like Die Toten Hosen and the Foo Fighters. “We get many orders from Asia and from the United States,” says Nik Huber. Today’s shipment will be going to Chicago.

As it happens, the eponymous founder of the company, now 49 years old, came to working with wood as a result of finding himself in a dilemma: when his plan to study architecture didn’t work out right away and he ended up on a waiting list, he decided to bridge the time by doing a carpentry apprenticeship. At some point his father, who at the time was a Lufthansa pilot, came back from a vacation and talked excitedly about a guitar-making course. Young Nik figured he might want to try his hand at that, too, and he was hooked from the very first minute.

ENABLING GLOBAL BUSINESS DUE TO AIRFREIGHT.

It was thanks to an encounter more than 20 years ago that Huber decided to turn his hobby into a vocation: at a concert in Frankfurt he showed the first guitar he had made himself to the legendary guitar maker Paul Reed Smith – who promptly became his mentor and guided him on his new career path. “He kept at me, drove me and was never, ever satisfied – thank God!” To this very day Huber still tries to build “the best guitar ever”. His catalog includes three body shapes, nine models and a long list of optional extras. Many of his customers have him create their own individual works of art. Airfreight is vital for Nik Huber, not only on a day like today when he ships finished guitars, but also when it comes to procuring supplies. This is why he participated in “Hessen goes global”, the corporate contest initiated by Lufthansa Cargo at the beginning of 2018. He finished up as one of the two winners, and he is sponsored by Lufthansa Cargo and UPS Global Freight Forwarding for one year.

|

The two companies receive free airfreight capacity of up to one container per month, as well as free ground transportation (door-to-door), and all customs clearance processes are handled for them. “For one thing, to me this means financial relief,” explains Huber. “For another, I’m also delighted that I can hand over the shipping side of things to professionals.” The logistics involving in making high-end guitars are challenging. It starts off with the wood, which this professional usually imports from California. “It needs to consist of long fibers and be dense, so that it can produce a good sound.” The preferred materials for Nik Huber, who once aspired to a career as a rock guitarist himself, are mahogany, ebony and rosewood. Rio rosewood, for example, is used for fingerboards. |

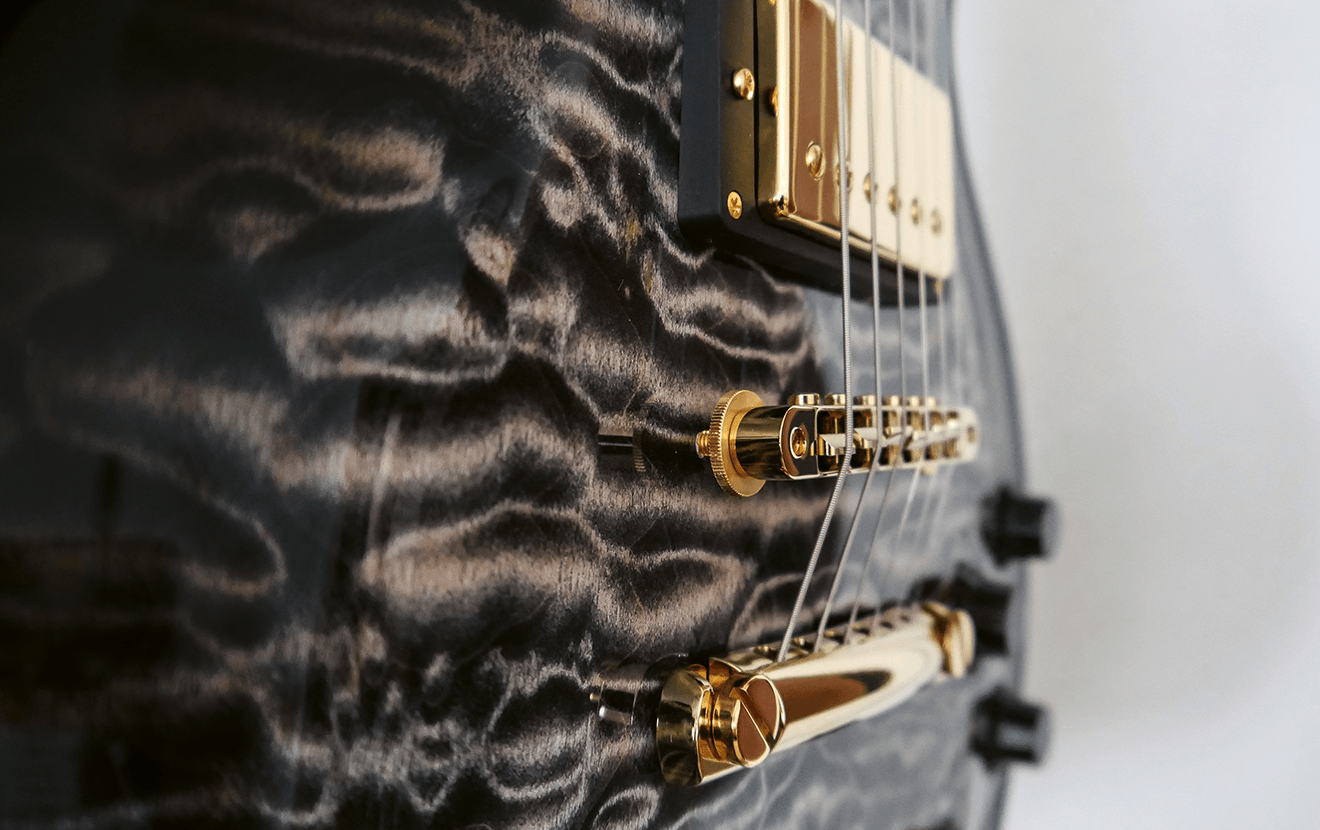

“The documentation required to import and export these timbers is extensive.” Safety plays a vital role in the transportation of these instruments: “Aside from the precious wood itself, our guitars are adorned with exclusive materials,” explains Huber. “Mother-of-pearl is commonly used, but I have also had customers who asked for gold and diamonds instead.” This calls for high standards – which Lufthansa Cargo meets with its special “Safe 2” product. “During shipment, I always know where my guitars are. We spend eight to twelve weeks working on each instrument. That’s a lot of blood, sweat and tears – the possibility that even just one of them might not make it to the destination doesn’t bear thinking about!” |

And sometimes things simply have to happen quickly: when a guitar has to arrive without fail before a musician goes on tour, when an exhibition copy is needed for a trade fair – or when the appropriate packaging is still missing: “For particularly high-end guitars, I have the cases hand made in California,” says Nik Huber. Just recently he had some of these delivered by “td.Flash,” Lufthansa Cargo’s product for very urgent shipments. “Airfreight has already saved my bacon quite a few times.”