The autopilots.

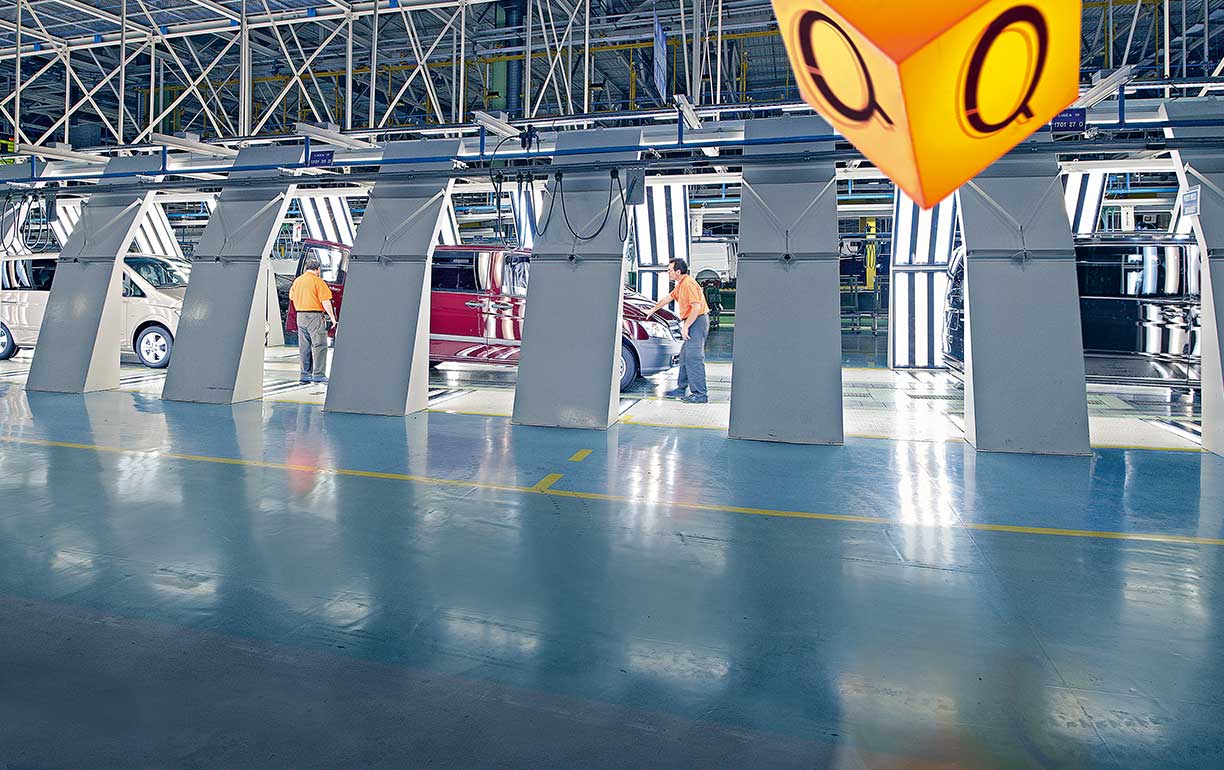

Considerable time pressure, a great deal of dangerous goods, valuable freight: the global automotive industry places strenuous demands on its logistics partners. Lufthansa Cargo has been reliably fulfilling these requirements for decades. Not only in emergencies but also at the start of serial production in overseas plants and in regular production supply.

Processes in the automotive industry are determined by a global division of labor as suppliers and major manufacturers migrate towards emerging markets. Countless vehicle parts are manufactured in Europe, for example, and then installed in Asia or North America. Major supply flows also move in the opposite direction as well as between North and South America or within Asia. These can include completely assembled vehicles, spare parts and prototype models.

To avoid high import tariffs, manufacturers sometimes dismantle their vehicles into individual parts – Completely Knocked Down (CKD) – before transporting them thousands of kilometers and reassembling them in the respective target markets.

Lead times in the industry are very short. Freight has to be delivered in clearly defined time slots so that it can be assembled just in time and preferably just in sequence. After all, inventory levels must be kept low, and yet production bottlenecks or even production stoppages have to be avoided at all costs.

In addition to this, many of the parts have a high product value or have to be transported as dangerous goods. Both are true in the case of rechargeable lithium-ion batteries, for example, which are becoming increasingly important thanks to the boom in hybrid vehicles.

All in all, this calls for the speed, transport security and flexibility that only airfreight can provide, particularly in time-critical situations or in emergencies, but increasingly also in regular production supply. And it requires a carrier like Lufthansa Cargo with a clear understanding of the requirements of manufacturers and suppliers, and solutions specifically developed for the industry.

Emergency.Solutions is Lufthansa Cargo’s express product for critical situations. When unforeseen circumstances disrupt a supply chain in such a way that production bottlenecks and even assembly line standstills cannot be ruled out, Emergency.Solutions provides the answer: within hours, Lufthansa Cargo can make deliveries ready for take-off and bring urgently needed parts to their destination quickly and safely. Capacity limitations are lifted and the progress of the express shipment is constantly documented, enabling the customer to trace it at all times.

- Emergency.Solutions – making the impossible possible

- Care/td – for dangerous goods utd.Flash – for urgent shipments

- td.Pro – for standard freight

- Courier.Solutions powered by time:matters – for personally supervised transit

Photos:

Daimler, Lufthansa Cargo, Ralf Kreuels

planet 2/2014

|

In the case of freight classed as dangerous goods, Care/td is the right product. The goods to be transported can include complete vehicles such as vintage cars, destined for trade fairs or even racing cars. This special solution even ensures that shock absorbers, airbags and other components or spare parts are transported safely to where they are needed. All transports carried out within the framework of Care/td comply with IATA’s Dangerous Goods Regulations. This transport solution ensures that the safety of people, the shipment, the environment and the aircraft is the prime consideration. Care/td can either be combined with td.Pro for standard freight or with the express solution td.Flash. Both provide excellent transport solutions for manufacturers and suppliers: td.Flash for crucial shipments and td.Pro for on-schedule delivery of parts, for example, at the start of serial production in overseas plants when regional suppliers have yet to be certified. |

The express product Courier.Solutions powered by time:matters is ideal for shipments that require minimal transit times. In this case, the freight, which is personally supervised, is loaded from aircraft to aircraft on the apron and accompanied by a staff member from Lufthansa Cargo’s partner time:matters. Sometimes the distance between a warehouse and an assembly line can be several thousand kilometers – and yet production stoppages must be avoided at all costs. That is why spare parts are often transported by airfreight.

|

Photos:

Daimler, Lufthansa Cargo, Ralf Kreuels

planet 2/2014